AN INTRODUCTION TO VEHICLE RESTRAINTS: WHAT IS A VEHICLE RESTRAINT AND WHY IS IT NECESSARY?

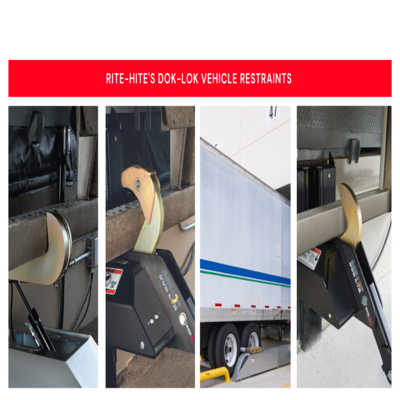

Before Rite-Hite created the vehicle restraint industry with the introduction of the Dok-

Lok in 1980 and the installation of the first vehicle restraint by Rite-Hite, the Global

Wheel-Lok in India in 2007, facilities relied on simply chocking tires (manually wedging

material against a truck’s wheel to help prevent movement). Over the years, an

increasing number of Indian companies have avoided the risk of grievous accidents and

loss of life by adopting different kinds of technologically advanced and cutting edge

vehicle restraints by Rite-Hite based on their loading dock applications.

What is a truck restraint or vehicle restraint?

Vehicle restraints, truck restraints or trailer restraints, are devices that latch onto the

back of trailers to keep them from separating from the loading dock during loading/

unloading. Along with restraining vehicles, they help improve safety, security and

productivity at the loading dock.

What is a dock lock?

Dok-Lok (generic term: dock lock) is a term for truck restraint/ vehicle restraint. Created

and originally patented by Rite-Hite in the United States, Dok-Lok has become the

industry term for this essential piece of equipment, widely used by shippers, distribution

centres and warehouses for the past 40 years.

Can you use a Dok-Lok on trailers and trucks?

Yes! The Dok-Lok can latch onto the rear-impact guard (RIG) or rear-wheel of the

trailer, depending on loading dock configuration, restraint and truck type. The rotating

hook design of many Dok-Loks wrap around the RIG, helping prevent trailer movement

while the wheel-based restraints (Global Wheel-Lok) restrain the rear-wheel of a trailer

to help secure the trailer in place during the loading process.

How do you install a vehicle restraint?

Installation of a vehicle restraint should always be handled by certified technicians who

can also provide repair and maintenance services at the loading dock.

What are the different types of vehicle restraints at the loading dock?

There are five types of vehicle restraints that you might find at the loading dock:

1. Rotating Hook Restraints feature a unique rotating hook design that wraps around

the RIG of the trailer, helping to reduce both horizontal and vertical movement during

loading activities.

2. Shadow Hook Restraints add an additional layer of safety by securing intermodal

containers or trailers with RIG obstructions.

3. Vertical Barrier Restraints feature a barrier that runs vertical to the RIG and helps

to limit horizontal movement of the trailer. Often a practical option for live loading, Rite-

Hite offers Ground Stored, Wall Mounted and Under Leveller style Vertical Barrier

Restraints.

4. Wheel-Lok Restraints secure the real-wheels of the trailer, rather than the rear

impact guard. Because of this, they can work with the largest variety of trailer types

including liftgates and trailers without an effective RIG.

5. Stabilising Trailer Restraints employ the same mechanics of the hook restraint

with the addition of hydraulic cylinders to stabilise horizontal and vertical movement

during loading/unloading on the truck, helping provide the smoothest transition from

facility floor to trailer bed.

Why do facilities need a vehicle restraint?

Aside from preventing costly trailer separation accidents, vehicle restraints serve as a

visual deterrence for cargo theft and help increase productivity and safety at the loading

dock.

What is trailer separation and what causes it?

Trailer separation occurs when a trailer inches away from the building or if a truck

departs from the loading dock unexpectedly, creating a dangerous gap between the

trailer and dock. Material handlers, forklifts and product can unknowingly drive off the

edge of dock, into the four foot drop off.

There are five typical causes of trailer separation:

1. Trailer Creep (Dock Walk): The trailer gradually moves away from the dock due to

the repeated momentum created by the forklift traveling in and out of the trailer with

sudden starts and stops. Eventually the leveler lip loses contact with the bed of the

trailer and a dangerous gap results between the trailer and dock. Air-ride

trailers compound the problem.

2. Early Departure: The truck driver mistakenly pulls away from the dock before

loading operations are complete. Oftentimes this is due primarily to lack of

communication between truck driver and dock workers. Light communication at the

dock helps mitigate this as well.

3. Landing Gear Failure: Weak or corroded landing gear give way under the impact

of loading and the nose of a spotted trailer collapses to the ground, forcing the rear of

the trailer, and the RIG, up vertically, and away, horizontally from the loading dock. If

not secured, this accident can cause the trailer to tip over, and create a cascading

“domino effect” as trailers one by one, are knocked into the adjacent trailer.

4. Trailer Upending: Often occurring with pup trailers, where the first heavy load

placed in the nose of the trailer causes the rear of the trailer to rise, forcing the rear of

the trailer, and the RIG, up vertically, and away from the dock.

5. Trailer Pop-Up: A heavy load on the rear of an empty (or near empty) trailer causes

the rear of the trailer to be forced toward the ground, popping the nose of the trailer in

the air.

How dangerous is trailer separation?

Trailer separation accidents are typically very serious and extremely costly due to direct

costs of medical care and product and equipment damage, as well as the indirect costs

of lost time and increased insurance premiums and shaken morale. Because of this,

Dok-Loks are an important investment to help with productivity, safety and security at a

facility.

Corporate Station Bangladesh is authorized distributor of Rite Hite in Bangladesh

market for dock management system. For any product or technical support contact with

Corporate Station Bangladesh.

Leave a Reply